Prefer to listen? Press play to hear this article.

Enter the PAPI—a visual system designed to help pilots maintain the correct glide path during approach. Easy to spot yet precise, PAPI lights are one of the first tools student pilots learn to interpret, and they remain just as vital for experienced airline captains. In this article, we’ll break down what PAPI is, how it works, and why it’s an essential skill for any pilot to master.

What is PAPI

The Precision Approach Path Indicator—or more widely abbreviated as PAPI—is a visual aid system installed at airports to help pilots maintain the correct approach angle during landing. You’ll usually find a row of four lights positioned next to the runway, typically on the left-hand side.

Each light projects either red or white, depending on the pilot’s approach angle. By quickly glancing at the combination of colors, a pilot can tell whether they’re too high, too low, or right on the correct glide path. The “sweet spot” is two white and two red lights—a simple but highly effective way to ensure a safe and stable approach.

PAPI was introduced in the late 20th century as an improvement over the older Visual Approach Slope Indicator (VASI). While VASI systems also used color-coded lights, they provided less precise feedback. PAPI’s four-light system allows for more accuracy and easier interpretation, which is why it has become the global standard at airports big and small.

How PAPI Works

At its core, PAPI is all about providing a visual glide path to the runway. The lights are installed in a row of four, each angled slightly differently so that they appear either white or red depending on the pilot’s approach. So no, they do not light up in different colors, somehow knowing at what height and angle the pilot is approaching the touchdown zone.

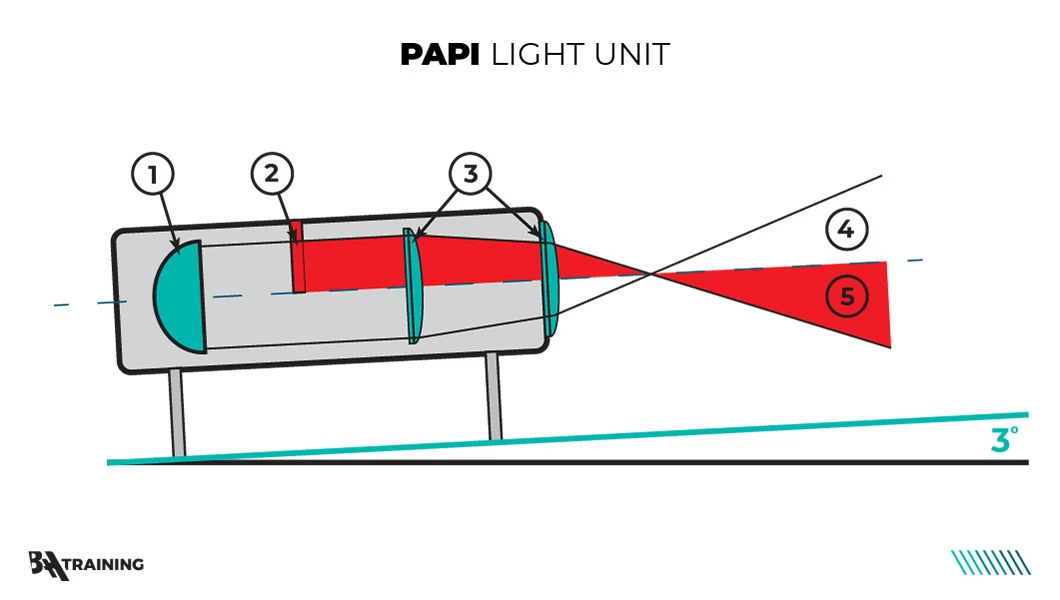

Each of the four light units consists of:

(1) a light source,

(2) a red filter, and

(3) two lenses.

The lower part of the beam is red (5), and the upper half of that same beam is white (4).

The lights are typically installed at a 3-degree angle, which is the target glide slope for a gentle descent angle, striking a balance between safety and efficiency. But airports can make that angle steeper if there is an obstacle clearance needed.

A good example is the London City Airport. Pilots landing here often face a descent angle of up to 5.5 degrees—much steeper than the standard. While certain aircraft, like the Embraer E190 and Airbus A318, are cleared to handle it, it’s not just about the planes.

Because of the airport’s shorter runway, nearby buildings, and unique terrain, specialized avionics, aircraft certification, and extra crew training are all part of the package. In fact, the Civil Aviation Authority (CAA) granted special permission for this steeper descent—mainly to make sure aircraft clear Canary Wharf’s skyline on the way in.

Reading PAPI Lights

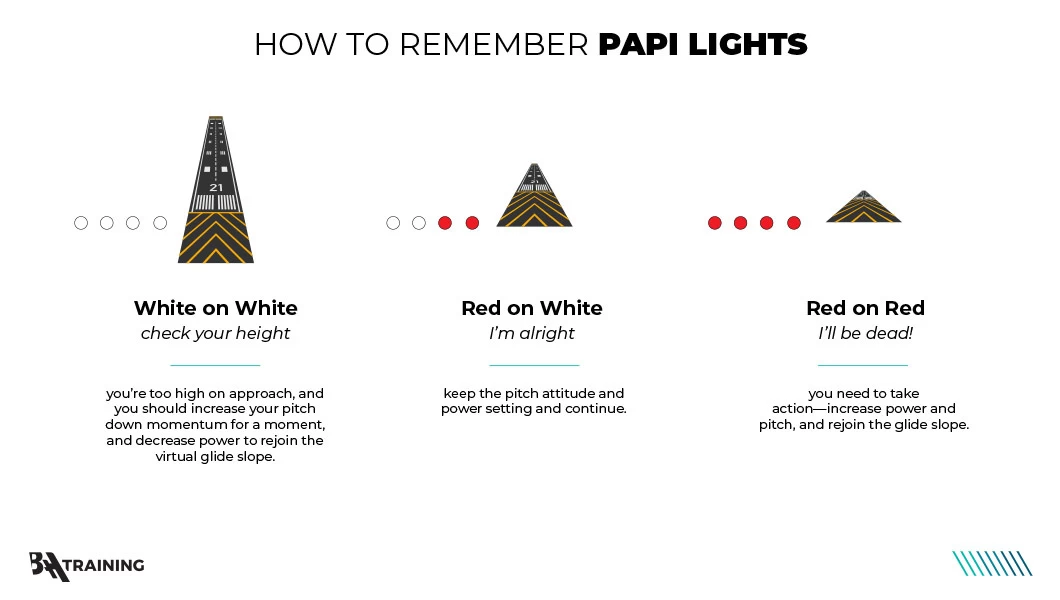

When the aircraft is aligned with the 3-degree slope, two lights appear white and two appear red. If the aircraft climbs above this angle, more lights appear white; if it descends below, more lights appear red:

- Four white lights → Too high.

- Three white, one red → Slightly high.

- Two white, two red → On glide path.

- One white, three red → Slightly low.

- Four red lights → Too low.

Why PAPI Matters for a Student Pilot

For student pilots, mastering landings is one of the biggest challenges in flight training. PAPI lights serve as a reliable visual guide, helping to build confidence and precision in this critical phase.

- Visual Awareness – see your aircraft’s position relative to the runway.

- Safer Landings – early feedback allows minor corrections before they become problems.

- Bridge Between Instruments & Visual – smooth transition from instrument flying to outside cues.

- Confidence Booster – knowing your glide path reduces stress and helps focus on other landing factors.

Ultimately, PAPI is a training tool that teaches precision, safety, and situational awareness. For pilots-in-training, learning to read these lights effectively is a milestone that sets the foundation for a lifetime of safe landings.

PAPI Isn’t Always the Right Cue

While the Precision Approach Path Indicator is a convenient and easy-to-read system, there are some nuances that pilots often notice.

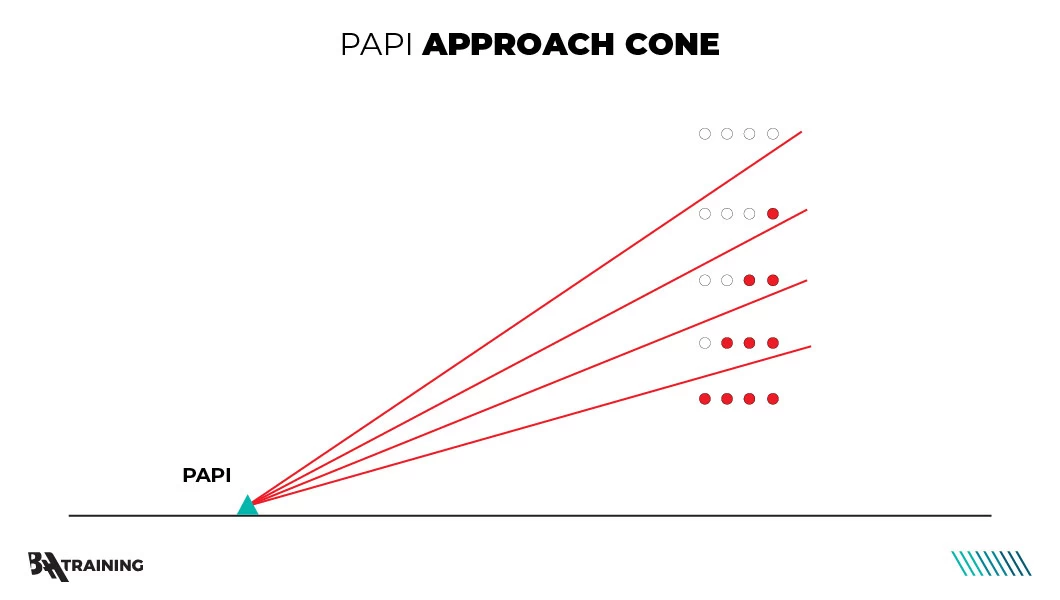

PAPI lights project in the shape of a cone. Far out on approach, the cone is wide, so it takes a significant change in altitude to move from, say, two white–two red lights to three or four whites. As you get closer to the runway, the cone narrows and those same light changes correspond to much smaller altitude differences.

What this means in practice is that in the last 200–300 feet, pilots may find that the PAPI lights shift quickly, but those small changes often aren’t critical. Many pilots instead focus on the touchdown zone, checking that their intended landing point is still aligned correctly, even if the PAPI shows three white or three red lights.

During full flight simulator training, it’s common for trainees to rely heavily on PAPI. When moving from sim training to real-world line operations, many pilots notice that overemphasizing the lights can become a habit. Experienced pilots often use PAPI to establish a good approach position, then shift focus to visual cues from the runway itself for the final few hundred feet.

In other words, PAPI is an excellent guide—but like many tools in aviation, it’s most effective when combined with visual judgment and experience, rather than used in isolation.

Bottom Line

PAPI lights are a trusted visual guide that helps pilots approach the runway safely and accurately. They help maintain the correct glide path and bridge the gap between instruments and what you see outside the cockpit. Combine PAPI cues with careful observation, gentle corrections, and a steady hand, and you’ll land like a pro every time. After all, every pilot starts with the lights—but the truly skilled know when to trust their own judgment.