Prefer to listen? Press play to hear this article.

These vital components form the foundation of aircraft design, allowing the plane to generate lift, stay balanced in the sky, and return to the ground safely during takeoff and landing. No matter how complex the aircraft may seem, its primary function is built around the same core aerodynamic forces and structural elements.

In this quick guide, we’ll break down the main components of an aircraft—from the fuselage to the landing gear—and highlight how these parts appear across both small training aircraft and large airliners. You’ll discover how flight controls, airplane wings, aircraft engines, and other critical systems vary between models, yet remain based on the same aviation principles. Shall we take off?

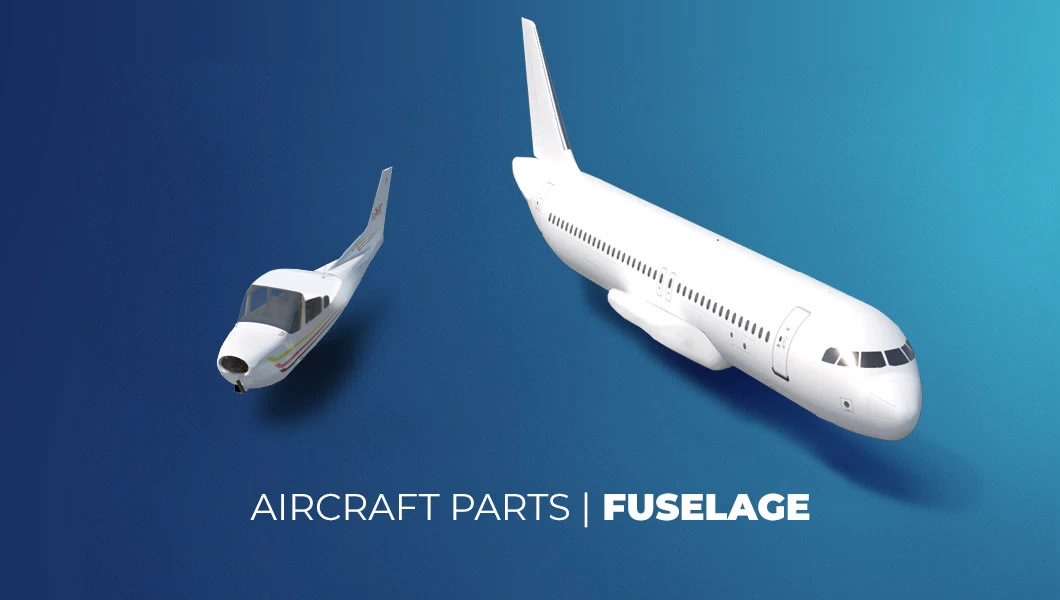

Fuselage, the Backbone of Flight

If an airplane were a story, the fuselage would be the main plotline—connecting everything from the cockpit drama to the tail-end resolution. This is the airplane’s main body, the central structure that ties all other parts together. It houses the flight crew, passengers, cargo, and often some of the aircraft’s most critical systems. It’s also where the forces of lift, drag, and thrust come together to decide whether you’re staying aloft or heading back to Earth.

In the Cessna 172S, for example, the fuselage is compact and functional, built with aluminum materials for strength without unnecessary weight. It seats four and offers excellent visibility, ideal for student pilots learning the ropes. The A320, on the other hand, plays in a different league. Its composite and aluminum fuselage is pressurized and stretched for efficiency, with a rear fuselage that supports cargo holds, cabin systems, and auxiliary power units (APUs).

Despite their size difference, both aircraft rely on their fuselage to maintain structural integrity, protect onboard systems, and provide aerodynamic shape that helps reduce drag. Think of it as the reliable spine of the aircraft—everything else hinges on it.

Quick Facts: Fuselage

- Also known as: The aircraft’s main body

- Primary function: Houses the cockpit, passenger cabin, cargo, and connects all major parts

- Materials used: Typically aluminum, composite materials, or both—chosen for structural integrity and fuel efficiency

- Shape matters: Designed to be sleek and aerodynamic to reduce drag and improve performance

- Bonus trivia: “Fuselage” comes from the French word fuselé, meaning “streamlined”—and that’s no coincidence

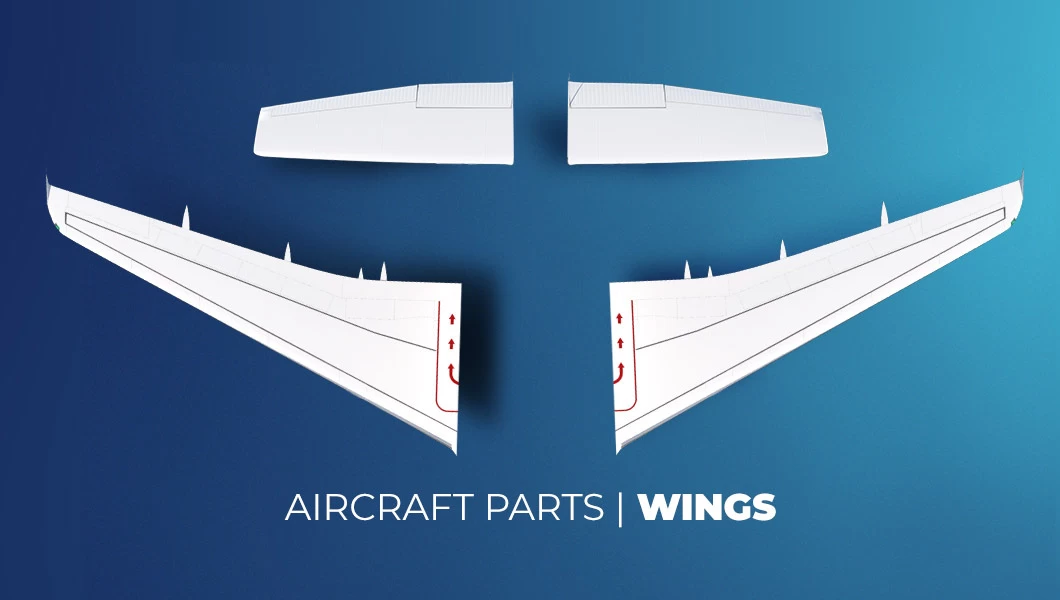

Wings, the Lift-Makers

Wings are the soul of flight. Quite literally the reason airplanes leave the ground in the first place. Their primary function is to generate lift by manipulating air pressure: air moves faster over the curved upper surface, creating lower pressure, while the slower-moving air underneath creates higher pressure. The result? Up you go, like magic—or, more accurately, physics.

On an aircraft like a Cessna, wings sit high, meaning they’re mounted above the fuselage. This provides better downward visibility, more ground clearance, and inherent stability—a dream for student pilots. Its wing structure is clean and straightforward, with fixed wing flaps on the trailing edge to help with slower speeds during takeoff and landing.

Commercial jets like A320, however, flip the script. With swept wings and complex control surfaces, like slats on the leading edge and multi-part flaps on the trailing edge, it’s built to optimize lift and reduce aerodynamic drag at different phases of flight. Tucked into those wings are large fuel tanks, essential for long-haul routes.

Quick Facts: Wings

- Primary function: Generate lift via pressure difference

- Key parts: Leading edge, trailing edge, flaps, ailerons, fuel tanks, and sometimes landing gear

- Materials: Typically made from aluminum or composite materials for strength and lightness

- Extra lift: Many modern wings include winglets to reduce induced drag

- Bonus trivia: Wings must be strong enough to flex significantly during turbulence without breaking—they’re designed to bend, not snap!

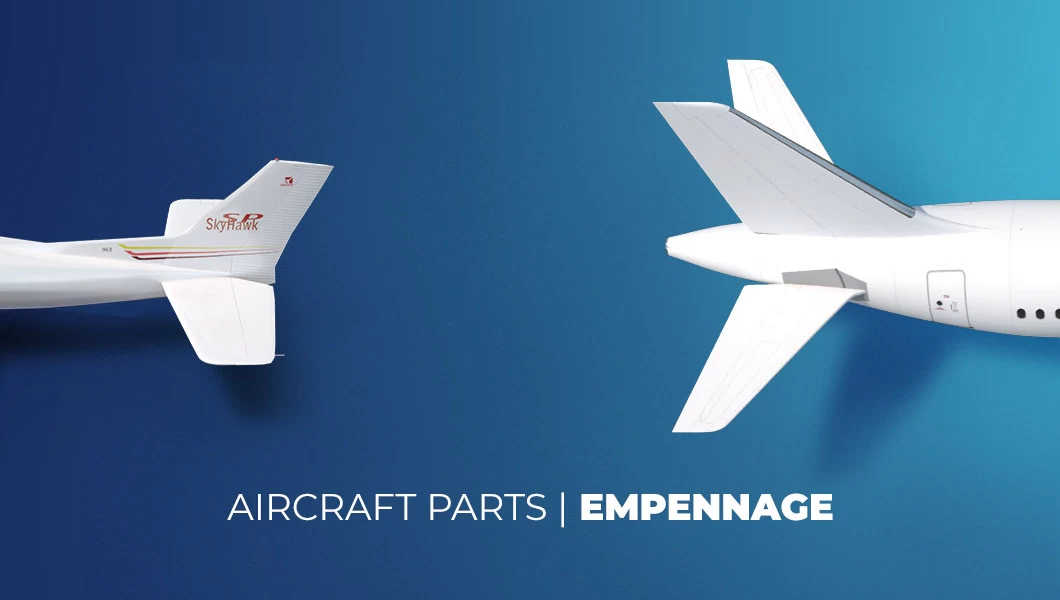

Empennage, Keeps It Together

Stability takes shape at the rear, in the empennage—or tail section. And while it might not be the flashiest part, it’s essential for stable, controlled flight. If the wings are the arms, think of the empennage as the spine and rudder of reason, constantly working to balance and steer the aircraft against shifting wind direction and aerodynamic forces.

It typically includes the horizontal stabilizer and vertical stabilizer, along with their respective primary control surfaces, the elevator and rudder. These surfaces control pitch (up and down) and yaw (side to side), helping the pilot keep the aircraft aligned and flying true.

On a Cessna, the empennage is classic and straightforward. A conventional tail setup with a fixed stabilizer and movable elevator and rudder, all directly controlled through cables and rods from the flight deck. Over on the Airbus, however, it’s built for precision at high speeds. Its tail assembly includes hydraulically actuated surfaces, electronic sensors, and redundant systems—the components behind your smooth arrival gate-side.

Despite the tech differences, the mission is the same: to keep the aircraft steady, responsive, and pointed in the right direction.

Quick Facts: Tail Section

- Also called: Tail assembly or stabilizing surfaces

- Main components:

- Horizontal stabilizer (controls pitch with the elevator)

- Vertical stabilizer (controls yaw with the rudder)

- Stability role: Helps maintain directional control, reduces drag, and balances the aircraft in flight

- Location: Mounted at the rear fuselage, though some aircraft use T-tail or V-tail configurations

- Bonus trivia: In flight, small adjustments made by the tail can feel huge—even a minor elevator input can change pitch dramatically, especially at higher speeds

Powerplant, Where the Thrust Happens

The powerplant is what gets the aircraft moving in the first place. It’s the aircraft’s engine and everything that makes it go—also known as the propulsion system. Whether it’s humming on a Cessna or roaring on a runway in an A320, the powerplant is responsible for generating the rotational energy that translates into forward motion.

For the Cessna, this means a reliable piston engine, a Lycoming IO-360-L2A, paired with a fixed-pitch propeller that has two or more blades. This setup may look modest, but it’s perfect for ground operations, low-speed flight, and learning the fundamentals of thrust and engine management.

Contrast that with the Airbus A320, which packs serious power: turbofan jet engines like the CFM56 or the newer Pratt & Whitney geared turbofans. These jet engines burn fuel with compressed air to generate massive amounts of thrust, delivering the performance needed for high-speed cruising and rapid takeoff. Plus, many are equipped with reverse thrust capabilities—because yes, jets can brake with air.

Your PILOT CAREER

starts with a first click

Despite their differences in noise, size, and complexity, both types of engines turn fuel into forward motion while balancing performance, safety, and efficiency.

Quick Facts: Powerplant

- Main function: Converts burning fuel into thrust to move the aircraft forward

- Types of aircraft engines: Piston engines, turboprop engines, jet engines, gas turbines

- Location: Typically mounted on the wings (A320) or nose (Cessna)

- Bonus trivia: Jet engines can suck in and compress over a thousand pounds of air per second. That’s a lot of wind management!

Landing Gear, the Unsung Legs of Aviation?

Think of the landing gear as the aircraft’s legs: tough, shock-absorbing, and always first to hit the ground running (literally). Its primary function is to support the aircraft during ground operations like taxiing, takeoff, and landing, absorbing the impact and helping the aircraft steer safely on the runway.

The Cessna is equipped with fixed landing gear—a no-fuss, always-visible setup with two main wheels under the wings and a nose wheel at the front. This tricycle configuration is simple and rugged, designed to handle bumps without the complexity (or maintenance needs) of retractable systems. It’s perfect for student pilots still perfecting their touchdown game.

Meanwhile, bigger aircraft like the A320 use a retractable landing gear system. A sleek, hydraulic setup that tucks away after takeoff to reduce aerodynamic drag and improve fuel efficiency. It includes two or more wheels per gear leg to support the heavier aircraft structure and is controlled from the flight deck, with fail-safes to ensure it deploys even in an emergency.

Quick Facts: Landing Gear

- Primary role: Supports the aircraft on the ground; enables takeoff and landing

- Landing gear types: Fixed, retractable, conventional (tailwheel), and tricycle

- Bonus trivia: Some larger aircraft have more than 20 wheels in total—just ask the Airbus A380. That’s a lot of tires to change.

Bottom Line

From the compact Cessna 172S to the sleek Airbus A320, aircraft may vary wildly in size, speed, and complexity—but they all share the same core anatomy. The fuselage, wings, empennage, powerplant, and landing gear are essential building blocks that make flight possible, safe, and efficient.

Whether you’re dreaming of your first solo flight or just curious about what keeps you aloft at 35,000 feet, understanding these vital components gives you a deeper appreciation of aircraft design, performance, and function. And while modern planes are packed with cutting-edge tech—from electronic flight instruments to composite materials—they’re all built on the same tried-and-true foundation of aerodynamic forces and smart engineering.

Want to go deeper? Check out our articles on cockpit instruments or stall recovery on an Airbus. The more you know, the smoother your next takeoff will feel—at the very least, mentally.