Today’s modern jets rely on the fly-by-wire system, a technology that swaps mechanical linkages for electronic signals. This shift has not only changed how aircraft are flown but also made flying safer, lighter, and more efficient. We’re ready to unpack what fly-by-wire means, where it came from, and why it’s the preferred standard in aviation today.

Prefer to listen? Press play to hear this article.

What Does Fly-By-Wire Actually Mean?

Fly-By-Wire this, Fly-By-Wire that—many use the term at any given time when talking about aircraft. But what is Fly-By-Wire? To start, it’s a type of flight control system. Mainly, aircraft can have mechanical, hydro-mechanical, powered (power-assisted), and fully electronic control systems, with hybrid arrangements in some aircraft models. If it has the word “wire” in it, it must mean cables, the “traditional” way, or mechanical way, of operating aircraft, right? Well, no.

The “wire” in Fly-By-Wire (or FBW) actually refers to the electrical wiring and signals that are used to transmit the pilot’s flight control inputs to the aircraft control surface. So, no cables, no pulleys, meaning FBW is a fully electronic control system.

When Was Fly-By-Wire Invented

Now, Fly-By-Wire has become almost synonymous with modern aviation and commercial aircraft, but it draws from draft designs of military aircraft. The FBW systems first emerged in the mid-20th century, initially tested in military aviation.

Roots In Military Aviation

The milestone moment came in 1972, when NASA modified an F-8 Crusader to fly with a fully digital Fly-By-Wire setup—no mechanical backup included.

The early Fly-By-Wire system actually borrowed guidance and control technology from the Apollo space program, adapting it for use in aircraft. The motivation was clear: traditional controls were heavy, complex, and prone to failure. Fly-By-Wire provided a lighter, more dependable, and more efficient way to manage flight.

The first production plane to fully embrace digital FBW was the General Dynamics F-16 Fighting Falcon in the 1970s. Its designers intentionally made the jet aerodynamically unstable to improve maneuverability, and the computerized flight controls supplied the stability needed to keep it safely in the air.

Soon after, Fly-By-Wire crossed into commercial aviation. The Airbus A320, introduced in 1988, became the first airliner to use a fully digital system. It also introduced flight envelope protections—automated safeguards that prevent unsafe pilot commands—ushering in a new standard of safety for passenger flights.

How a Fly-By-Wire Control System Works?

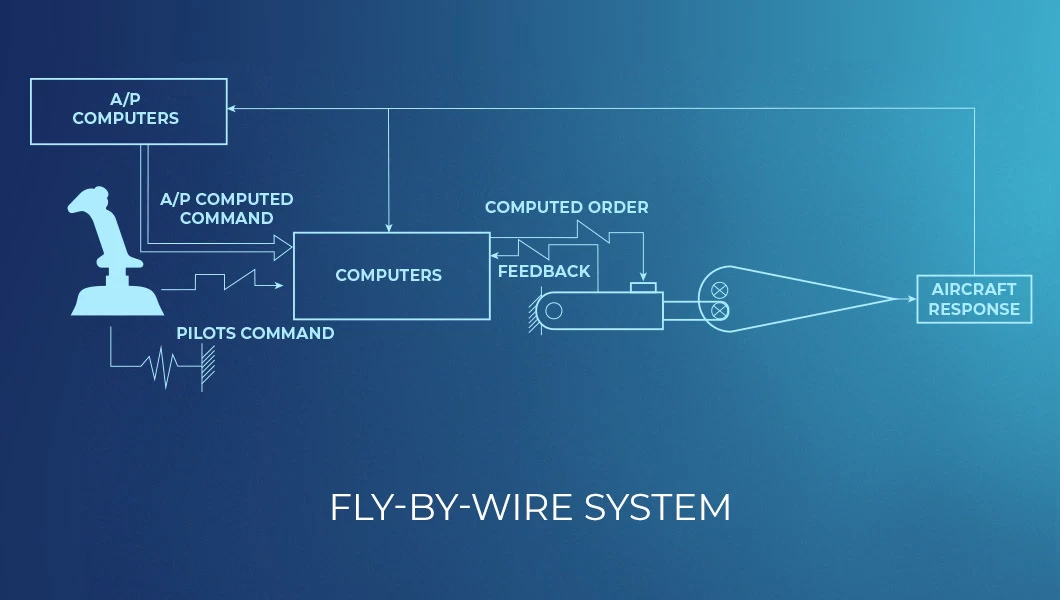

At its core, FBW replaces the traditional web of mechanical cables and pulleys with an electronic control system. Instead of a direct physical link, pilot inputs (or autopilot) are processed by onboard computers, which then command the aircraft’s control surface through electrical signals.

Here’s how it works in practice:

- Pilot input: Moving the control column or sidestick generates an electronic signal.

- Computer processing: The flight control computers (FCCs) interpret the pilot commands and figure out the intended maneuver.

- Flight control surface movement: The computers calculate how the elevators, ailerons, rudder, and other flight control surfaces should move, while applying control laws to maintain stability and ensure flight safety.

- Actuator response: Commands are sent to flight control surface actuators, which physically move the surfaces.

- Feedback loop: Sensors monitor the surfaces in real time, sending data back to the computers to correct any deviations.

- Safety protections: Many systems include flight envelope protections that prevent unsafe maneuvers and automatic stability features that can assist without additional pilot inputs.

- Redundancy: Multiple computers and signal channels provide backup, ensuring the aircraft remains controllable even if one system fails.

In short, FBW replaces heavy, failure-prone mechanical linkages with an electronic feedback loop—delivering faster responses, greater precision, and enhanced safety.

Examples of Fly-By-Wire Aircraft

Fly-By-Wire might be most famously linked with Airbus, but it’s far from an Airbus-only technology. Yes, Airbus was the first manufacturer to introduce it into commercial service, but today FBW is the rule rather than the exception across new-generation airliners, military jets, and even business aircraft.

Here are some examples where fly-by-wire has become standard:

Commercial Airliners

- Airbus A320 family (A318, A319, A320, A321): the pioneer of digital FBW in commercial service, introduced in 1988.

- Airbus A330, A350 XWB, and A380: all equipped with highly advanced FBW systems.

- Boeing 777 and 787 Dreamliner: Boeing’s long-haul flagships, both using digital FBW with strong flight envelope protections.

- Embraer E2 Jet Family (E175-E2, E190-E2, E195-E2): regional jets that adopted FBW for smoother handling and efficiency.

- Embraer Legacy 450/500 (Praetor 500/600): business jets featuring modern FBW controls.

- Dassault Falcon 7X: the first business jet to fly with FBW.

Military Aircraft

Similar ARTICLES

- General Dynamics F-16 Fighting Falcon: the first operational fighter to go digital with FBW.

- Lockheed Martin F-35 Lightning II and F-22 Raptor: stealth fighters where FBW is central to their extreme agility.

- Boeing F/A-18 Hornet and F-15E Strike Eagle: both incorporate FBW for improved control.

- NASA’s F-8 Crusader (1972): the historic testbed that proved digital FBW could work in fixed-wing aircraft.

Seeing how widespread FBW has become, it’s easy to assume everyone has a clear picture of how it works. In reality, the system is often surrounded by myths and half-truths that can make it seem more mysterious than it really is.

Misconceptions About FBW System

Fly-By-Wire only refers to the Airbus flight control style.

Both Airbus and Boeing rely on FBW, though they’ve chosen different approaches. Boeing kept the familiar control yoke, while Airbus opted for side-sticks—but underneath, both are powered by the same core technology.

Fly-By-Wire means the pilot has less control, or the computer “flies the plane.”

FBW doesn’t override pilot commands; it enhances them. The system interprets inputs, adds stability, and blocks unsafe maneuvers, but every action still comes from the pilot. Think of it as technology that strengthens, not replaces, human control.

FBW systems are inherently risky due to reliance on electronics.

Your PILOT CAREER

starts with a first click

Redundancy is the name of the game. Multiple computers, backup channels, and fail-safes make FBW not only reliable but often safer than older, purely mechanical setups.

Fly-By-Wire eliminates all mechanical backups.

While the main controls are electronic, FBW aircraft typically carry layers of redundancy—backup computers, independent power sources, and in some cases, even limited mechanical or hydraulic systems to keep things safe in a worst-case scenario.

Fly-By-Wire vs Cable

Fly-By-Wire and traditional cable-based flight control systems offer two very different approaches to managing an aircraft. We already know that in FBW aircraft, pilot inputs are converted into electronic signals that are interpreted by flight control computers. These computers don’t just take the pilot’s inputs and direct the flight control surface actuators to move the control surfaces. They can also coordinate engine controls to optimize performance and maintain stability. Traditional cable systems work differently: pilot commands travel through rods, pulleys, and control cables, creating a direct physical connection to the surfaces.

One clear advantage of FBW technology is its weight savings. By replacing mechanical linkages with computers, Fly-By-Wire airplanes can be lighter, use smaller stabilizers, and make more efficient use of the airframe. Mechanical systems, with their network of cables and pulleys, remain heavier and less streamlined. Conventional mechanical systems, with their network of cables, pulleys, and hydraulic lines, are naturally heavier.

Safety and flight protection are also major differences. FBW-based aircraft use control laws programmed into the flight control computers, providing stability augmentation, flight envelope protection, and system redundancy. Mechanical systems offer no automatic safeguards—pilots are fully responsible—but failures tend to be gradual rather than sudden.

Handling characteristics are another area where FBW shines. Fly-By-Wire controls allow responsiveness and stability to be fine-tuned by software, while conventional mechanical controls rely solely on aircraft design. FBW aircraft use artificial control forces to simulate feel, whereas cable systems provide direct tactile feedback to the pilot via the control column or control wheel.

Maintenance approaches differ as well. FBW systems require specialized knowledge of electronics and software diagnostics, while cable-based mechanical controls demand regular physical inspections and adjustments to cables, pulleys, and hydraulic systems.

Bottom Line

Fly-By-Wire has changed how aircraft are flown. Computers replace heavy mechanical linkages, making FBW airplanes lighter, more responsive, and safer. Pilot commands are interpreted and sent to the flight control surfaces, while protections prevent unsafe maneuvers—all without taking control away from the pilot.

Compared to cable-based systems, FBW offers greater precision, flexibility, and reliability. Mechanical setups give direct tactile feedback but lack the advanced handling and safety features of Fly-By-Wire technology.

Now standard in commercial and military aircraft, FBW is the backbone of modern aviation—ensuring smoother handling, enhanced safety, and control that was once unimaginable.